So...the kitchen faucet sprang a leak and we decided to remodel the whole room. (I'm using the royal we, in case you were wondering.)

Let me back up. I came home from work a few weeks ago, and went to get a glass of water, and ended up with wet socks. (Never a good feeling, that.) The culprit? The cold water side of the kitchen faucet. Jesse was out with friends, so I was home alone with a potentially major plumbing issue. I did what any self-sufficient adult would do: I panicked and ran to Google.

This army is run by General Issues.

The first order of business was to turn off the supply lines to the faucet itself, which the internet helpfully noted would be under the sink. Except when I looked, there weren't any valves on the supply lines under the sink. After further investigation, I found the cold water valve on the ceiling in the basement, but the hot water valve was...nowhere. So the next logical step was to turn off the water at the hot water tank.

Helpful plumbing assistant Sassafras.

Because our house is a carefully-assembled series of "What the hell were they thinking?!" constructions, I was (mostly) not surprised to find out that there IS no hot water cut off valve at the tank. Yep, there were 40 gallons of hot water between me and a replacement gasket. So I did the obvious next step: opened myself a beer and called my mother.

The consensus was that we needed a plumber. Since the leak was contained (cold water was off, horrible warning taped on sink, Jesse warned via text, etc) it wasn't an emergency situation. The next morning, I called the best plumber Angie's List could recommend, and the scheduler helpfully noted that the first available appointment was October 6th...ten days away.

Well, it's not like we've been cooking much anyway. I took the appointment, and resolved to make room in the laundry sink for dishes.

THE SINK

In the meantime, there was an IKEA sink somewhere in transit, slowly making its way to my waiting arms. This sink is the pinnacle of my kitchen remodel hopes.

The consensus was that we needed a plumber. Since the leak was contained (cold water was off, horrible warning taped on sink, Jesse warned via text, etc) it wasn't an emergency situation. The next morning, I called the best plumber Angie's List could recommend, and the scheduler helpfully noted that the first available appointment was October 6th...ten days away.

Well, it's not like we've been cooking much anyway. I took the appointment, and resolved to make room in the laundry sink for dishes.

THE SINK

In the meantime, there was an IKEA sink somewhere in transit, slowly making its way to my waiting arms. This sink is the pinnacle of my kitchen remodel hopes.

The IKEA Domsjo double-bowl. It's huge. It's lovely. I need it.

Our kitchen is expansive. Our sink is currently cast iron and lemon yellow, which is cute, but not really the look I'm going for.

My decorating technique has always been to figure out what I like, and then to figure out how I can get it. (Or at least recreate it, which is often the tougher task, since I unfortunately have very expensive tastes.)

My Pinterest board is full of kitchens like this:

My Pinterest board is full of kitchens like this:

Source: Pinterest, that beloved timesuck

What do these gorgeous kitchens have that ours does not? Cabinets to the ceiling, and farmhouse sinks. There's a gross soffit above our cabinets, but hey, I can remove that. The issue I was running into, however, was that sinks? Are really really freaking expensive. Like thousands of dollars expensive. So when I found the IKEA Domsjo for $300, I almost died. And then I really did almost die, because it wasn't in stock.

Turns out, there were some supply issues with the double-bowl Domsjo, and for almost a month, I had it saved in my online shopping cart, biting my nails because it was no longer posted on the website and looked very much like it would be discontinued. The first paycheck I could afford it, I sprang, and my giant sink began lumbering on its two-week journey across the country. (Apparently Boston was only place that had it in stock.)

This story ends happily, though, because I have my fancy sink, and it's now back in stock at my local IKEA, so everyone else can have a fancy sink, too.

THE REMODEL

When I ordered the sink, I didn't really have a plan, besides "OH GOD IT'S ONE THIRD THE PRICE OF ALL THE OTHER SINKS AND IF IT GETS DISCONTINUED I WILL CRY BUY IT NOW BUY IT NOW!!" (All you advertisers, take note: the scarcity argument actually works.) Then, our faucet broke, and suddenly our sink was due to arrive two days before the plumber. And suddenly it made sense to install a new faucet sink with the new sink. And since the sink was going to be replaced, I could redo the counters like I'd been wanting. And if I was going to redo the counters, I might as well take down the soffits beforehand, so falling drywall wouldn't damage the new surface.

It's a slippery slope over here at Left of Center, but I managed to convince my project manager (aka Jesse) that it would in fact be worth it.

I started my three-day weekend with the joyous arrival of The Sink. Much crooning ensued.

Then, the soffit demolition started.

Being the crazy person I am, I'd researched everything I could find about soffits prior to demo. The internet indicated that almost all soffits were just a simple frame and drywall.

That is not what I found.

Yep, that's drywall over 1/2 inch plywood, which is covering up...a heating duct. WHO BUILDS SOFFITS OUT OF PLYWOOD? I was not warned about this.

The best part? The soffit wouldn't even have been necessary if the original builders had put the heating duct eight inches higher. Yep, they sacrified something like 30 square ft of potential cabinet space because they didn't feel like moving the duct.

I called Incredible Builder Dad. His sage advice was to put the drywall back up, and then wait a year or two for when we could take the kitchen down to the studs.

Sorry, Dad, I'm pretty sure you said, "Use the reciprocating saw and do it now."

It was gross. Like, beyond gross. The entire soffit apparently served as a mouse superhighway for the last thirty years, and I was SO GLAD for my super filter mask because YUCK.

Here, speaking of filters, have an artistic shot of the chaos. Yes, I did also pull down the wall next to the furnace chimney. Why? Um, it was easier than the soffit. Also, it was there. Jesse wasn't home. Did I need a reason?

Finally, after two crazy days of kitchen demo, the soffits were out, the heating duct was duly adjusted, and it was time to do the countertops.

If money were no object, I would have put in soapstone. It's gorgeous and patinas nicely. You can sand out scratches, it's non-reactive, and so much more user-friendly than granite or marble. From everything I've read, it's very much a "living" surface, one that changes over time and ages with the house.

Except not only is soapstone very very expensive, it's almost impossible to source on this side of the country. Apparently it's easier to find on the East Coast, where it's a much more common material, but here on the left coast, you have to special order it, which makes it even more expensive. And we have a lot of counter space. It just wasn't going to happen, at least not in this decade.

In the meantime, our countertops were navy blue laminate, and although they were in mostly usable condition, it wasn't very pretty. I'm a superficial person, I need it to be pretty. I mean, with our gorgeous new sink, the entire kitchen needed a makeover.

After extensive research, I discovered a technique online where I could skimcoat the existing laminate with a concrete-like product called Ardex Feather Finish. By adding black concrete pigment, I could approximate the color and texture of the soapstone I wanted, for a fraction of the cost.

The entire process of skimcoating was 100% easier than I expected. Because some of the laminate was peeling, I added a layer of 1/4 inch backerboard to all the countertops, so the Ardex had a perfect surface to adhere to. Each layer was supposed to take 15 minutes to dry, but it ended up being more like 12 hours; I was being enthusiastic about putting it on.

I could have gotten away with one or two layers of the Feather Finish, but I wasn't achieving the charcoal color I wanted, so I ended up doing four layers, with the proper color ending up being one bottle of Quickrete charcoal concrete pigment per box of Feather Finish.

Once the final layer was dry, I sanded it first with 60 grit sandpaper, to knock down all the large lumps, and then 120 grit to polish it up. I was supposed to sand between each layer, but I'm lazy, so lumps from the earlier coats ended up showing through the final coat. The effect actually looks like striations in real stone, so that was a pleasant surprise.

The end result is fantastic. I love it, and it's so much better than what I could have hoped for. The texture is very much like honed stone, and there are just enough imperfections that it won't be too much of a tragedy the first time I drop a heavy bowl on it.

Right now, it's got two coats of 511 Impregnator Sealer on it to prevent staining and make it water-resistant, so it's darkened up quite a bit, and when that's cured in a day or two, I'll put on two or three coats of Minwax Polycrylic on it to prevent scratches. I use Polycrylic to seal all of my projects - including the kitchen table I refinished at the old apartment - and I've never once had an issue with scratching or peeling, and once it's cured, both it and the Impregnator are food-safe.

So. Counters are done. Time to install the gorgeous sink!

Before I'd done the Feather Finish, I'd made a template of the sink from the sink box (carefully tracing around the edges of the sink to ensure proper fit) and cut the counter to size. It should have been perfect...except it wasn't, as I am coming to realize about this house. We couldn't get it in. So we pulled it back out, and sawed some more off the edge of the cabinets, and tried again.

Still nope. So out it comes, and we saw some more off, and that doesn't work, so we cut from a different area, and that STILL doesn't work. I MEASURED THE DAMN SINK. ITS CARDBOARD TEMPLATE HAS AN INCH OF SPACE AROUND THE EDGE! There is NO REASON this sink should not be fitting, except it just. WON'T.

We haul it back out - keep in mind that this sink weighs more than I do - and I hack quite a bit off the cabinets.

At this point, it's getting close to 9pm. We both have to be up by 6am, and I, for one, would REALLY like to shower and get the countertop dust out of my hair, but the water is still off because the faucet is disconnected, so we can't. So we try to wiggle it in place one more time.

And then this happens:

In case you can't tell, that's the corner of my beautiful, brand new sink, no longer attached. I almost cried.

That's when we decided to call it a night.

The next day, we inspected the damage. It turns out that with a little epoxy, the crack will be almost invisible, and the sink itself isn't structurally damaged. After way too much finagling, it is, at this point, precisely level and more or less in position.

THE FAUCET

After the ordeal of the sink, I thought the faucet would be fairly straightforward. Oh, how innocent I was.

Jesse and I had spent the better part of the week prior trying to find a faucet we liked. Our options were limited by a) budget and b) the single hole in the Domsjo. I really wanted something in a warm, classic brass, but in the end, we settled on a Hjuvik from IKEA. It wasn't the cheapest, but it was big enough for our giant sink, and it felt much more sturdy than comparable models at the plumbing store. Plus, it came with a 10-year warranty, and warranties are good, right?

It turns out that most IKEA faucet supply lines do not connect up with American plumbing without a little help. The supply lines were 3/8", while the lines from the wall were 1/2". After reading many horror stories online about Frankensteinian DIY line connections, we ended up just finding a couple of 3/8" to 1/2" adapters at Home Depot. While we were there, we picked up a few extra parts for the drain assembly, since I'd been wrestling with the stupid garbage disposal for the last few hours and couldn't seem to make any headway.

So we got home, and managed to cobble together the drain pipes, with no small amount of silicone goo. Then, we hooked up all the supply lines, and discovered that they both LEAKED. And not just a little bit. We took our degraded gaskets to the plumbing store down the street, and were told that not only did they not carry that size, we'd have to run entirely new line. Yes, we will eventually, since we've got polybutylene lines that are no longer up to code, but we were flying to Alabama the next day for a weeklong vacation, and our sink was still dripping a quart of water every few hours. (And remember, there is no water shutoff. Even turning it off at the curb didn't seem to make any difference.)

Long story short, I gobbed everything up with approximately a pound of silicone goo, and then we left on vacation. (That's another post for another time.) While we were gone, I ordered some assorted gaskets from Amazon, and they were waiting for us when we got home. Tonight, I spent three hours with my head under the sink, carefully putting everything back together and chasing drips around, but we've finally done it.

We're not going to win any prizes for beauty, but the faucet works, the drain works, and nothing is leaking (knock on wood).

My gorgeous sink is installed and functional, and we can FINALLY go back to taking hot showers without having to go to the basement to turn the water on first. Plumbing would be SO MUCH EASIER if it didn't involve water.

Turns out, there were some supply issues with the double-bowl Domsjo, and for almost a month, I had it saved in my online shopping cart, biting my nails because it was no longer posted on the website and looked very much like it would be discontinued. The first paycheck I could afford it, I sprang, and my giant sink began lumbering on its two-week journey across the country. (Apparently Boston was only place that had it in stock.)

This story ends happily, though, because I have my fancy sink, and it's now back in stock at my local IKEA, so everyone else can have a fancy sink, too.

THE REMODEL

When I ordered the sink, I didn't really have a plan, besides "OH GOD IT'S ONE THIRD THE PRICE OF ALL THE OTHER SINKS AND IF IT GETS DISCONTINUED I WILL CRY BUY IT NOW BUY IT NOW!!" (All you advertisers, take note: the scarcity argument actually works.) Then, our faucet broke, and suddenly our sink was due to arrive two days before the plumber. And suddenly it made sense to install a new faucet sink with the new sink. And since the sink was going to be replaced, I could redo the counters like I'd been wanting. And if I was going to redo the counters, I might as well take down the soffits beforehand, so falling drywall wouldn't damage the new surface.

It's a slippery slope over here at Left of Center, but I managed to convince my project manager (aka Jesse) that it would in fact be worth it.

I started my three-day weekend with the joyous arrival of The Sink. Much crooning ensued.

Seriously, that is the biggest box in the world.

And that box contained the biggest sink in the world.

IT'S SO PRETTY I'M GONNA DIE.

Then, the soffit demolition started.

Safety first!

Being the crazy person I am, I'd researched everything I could find about soffits prior to demo. The internet indicated that almost all soffits were just a simple frame and drywall.

That is not what I found.

Yep, that's drywall over 1/2 inch plywood, which is covering up...a heating duct. WHO BUILDS SOFFITS OUT OF PLYWOOD? I was not warned about this.

The best part? The soffit wouldn't even have been necessary if the original builders had put the heating duct eight inches higher. Yep, they sacrified something like 30 square ft of potential cabinet space because they didn't feel like moving the duct.

I called Incredible Builder Dad. His sage advice was to put the drywall back up, and then wait a year or two for when we could take the kitchen down to the studs.

Sorry, Dad, I'm pretty sure you said, "Use the reciprocating saw and do it now."

It was gross. Like, beyond gross. The entire soffit apparently served as a mouse superhighway for the last thirty years, and I was SO GLAD for my super filter mask because YUCK.

Here, speaking of filters, have an artistic shot of the chaos. Yes, I did also pull down the wall next to the furnace chimney. Why? Um, it was easier than the soffit. Also, it was there. Jesse wasn't home. Did I need a reason?

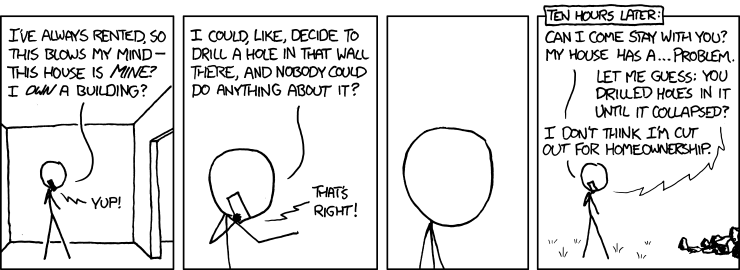

I'm pretty sure the author of xkcd is watching me on hidden cameras.

Finally, after two crazy days of kitchen demo, the soffits were out, the heating duct was duly adjusted, and it was time to do the countertops.

If money were no object, I would have put in soapstone. It's gorgeous and patinas nicely. You can sand out scratches, it's non-reactive, and so much more user-friendly than granite or marble. From everything I've read, it's very much a "living" surface, one that changes over time and ages with the house.

Source: Pinterest

Except not only is soapstone very very expensive, it's almost impossible to source on this side of the country. Apparently it's easier to find on the East Coast, where it's a much more common material, but here on the left coast, you have to special order it, which makes it even more expensive. And we have a lot of counter space. It just wasn't going to happen, at least not in this decade.

In the meantime, our countertops were navy blue laminate, and although they were in mostly usable condition, it wasn't very pretty. I'm a superficial person, I need it to be pretty. I mean, with our gorgeous new sink, the entire kitchen needed a makeover.

After extensive research, I discovered a technique online where I could skimcoat the existing laminate with a concrete-like product called Ardex Feather Finish. By adding black concrete pigment, I could approximate the color and texture of the soapstone I wanted, for a fraction of the cost.

The entire process of skimcoating was 100% easier than I expected. Because some of the laminate was peeling, I added a layer of 1/4 inch backerboard to all the countertops, so the Ardex had a perfect surface to adhere to. Each layer was supposed to take 15 minutes to dry, but it ended up being more like 12 hours; I was being enthusiastic about putting it on.

I could have gotten away with one or two layers of the Feather Finish, but I wasn't achieving the charcoal color I wanted, so I ended up doing four layers, with the proper color ending up being one bottle of Quickrete charcoal concrete pigment per box of Feather Finish.

Once the final layer was dry, I sanded it first with 60 grit sandpaper, to knock down all the large lumps, and then 120 grit to polish it up. I was supposed to sand between each layer, but I'm lazy, so lumps from the earlier coats ended up showing through the final coat. The effect actually looks like striations in real stone, so that was a pleasant surprise.

Yep, that's my ShopVac taped to my orbital sander. A poor girl's dust reduction system, if you will.

The end result is fantastic. I love it, and it's so much better than what I could have hoped for. The texture is very much like honed stone, and there are just enough imperfections that it won't be too much of a tragedy the first time I drop a heavy bowl on it.

Right now, it's got two coats of 511 Impregnator Sealer on it to prevent staining and make it water-resistant, so it's darkened up quite a bit, and when that's cured in a day or two, I'll put on two or three coats of Minwax Polycrylic on it to prevent scratches. I use Polycrylic to seal all of my projects - including the kitchen table I refinished at the old apartment - and I've never once had an issue with scratching or peeling, and once it's cured, both it and the Impregnator are food-safe.

So. Counters are done. Time to install the gorgeous sink!

Before I'd done the Feather Finish, I'd made a template of the sink from the sink box (carefully tracing around the edges of the sink to ensure proper fit) and cut the counter to size. It should have been perfect...except it wasn't, as I am coming to realize about this house. We couldn't get it in. So we pulled it back out, and sawed some more off the edge of the cabinets, and tried again.

Still nope. So out it comes, and we saw some more off, and that doesn't work, so we cut from a different area, and that STILL doesn't work. I MEASURED THE DAMN SINK. ITS CARDBOARD TEMPLATE HAS AN INCH OF SPACE AROUND THE EDGE! There is NO REASON this sink should not be fitting, except it just. WON'T.

We haul it back out - keep in mind that this sink weighs more than I do - and I hack quite a bit off the cabinets.

I'm pretty sure the N is for NOT FITTING.

At this point, it's getting close to 9pm. We both have to be up by 6am, and I, for one, would REALLY like to shower and get the countertop dust out of my hair, but the water is still off because the faucet is disconnected, so we can't. So we try to wiggle it in place one more time.

And then this happens:

In case you can't tell, that's the corner of my beautiful, brand new sink, no longer attached. I almost cried.

That's when we decided to call it a night.

The next day, we inspected the damage. It turns out that with a little epoxy, the crack will be almost invisible, and the sink itself isn't structurally damaged. After way too much finagling, it is, at this point, precisely level and more or less in position.

THE FAUCET

After the ordeal of the sink, I thought the faucet would be fairly straightforward. Oh, how innocent I was.

Jesse and I had spent the better part of the week prior trying to find a faucet we liked. Our options were limited by a) budget and b) the single hole in the Domsjo. I really wanted something in a warm, classic brass, but in the end, we settled on a Hjuvik from IKEA. It wasn't the cheapest, but it was big enough for our giant sink, and it felt much more sturdy than comparable models at the plumbing store. Plus, it came with a 10-year warranty, and warranties are good, right?

The inspiration, via Pinterest.

The reality, via IKEA.

It turns out that most IKEA faucet supply lines do not connect up with American plumbing without a little help. The supply lines were 3/8", while the lines from the wall were 1/2". After reading many horror stories online about Frankensteinian DIY line connections, we ended up just finding a couple of 3/8" to 1/2" adapters at Home Depot. While we were there, we picked up a few extra parts for the drain assembly, since I'd been wrestling with the stupid garbage disposal for the last few hours and couldn't seem to make any headway.

So we got home, and managed to cobble together the drain pipes, with no small amount of silicone goo. Then, we hooked up all the supply lines, and discovered that they both LEAKED. And not just a little bit. We took our degraded gaskets to the plumbing store down the street, and were told that not only did they not carry that size, we'd have to run entirely new line. Yes, we will eventually, since we've got polybutylene lines that are no longer up to code, but we were flying to Alabama the next day for a weeklong vacation, and our sink was still dripping a quart of water every few hours. (And remember, there is no water shutoff. Even turning it off at the curb didn't seem to make any difference.)

Long story short, I gobbed everything up with approximately a pound of silicone goo, and then we left on vacation. (That's another post for another time.) While we were gone, I ordered some assorted gaskets from Amazon, and they were waiting for us when we got home. Tonight, I spent three hours with my head under the sink, carefully putting everything back together and chasing drips around, but we've finally done it.

We're not going to win any prizes for beauty, but the faucet works, the drain works, and nothing is leaking (knock on wood).

My gorgeous sink is installed and functional, and we can FINALLY go back to taking hot showers without having to go to the basement to turn the water on first. Plumbing would be SO MUCH EASIER if it didn't involve water.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-EFFECTS.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)